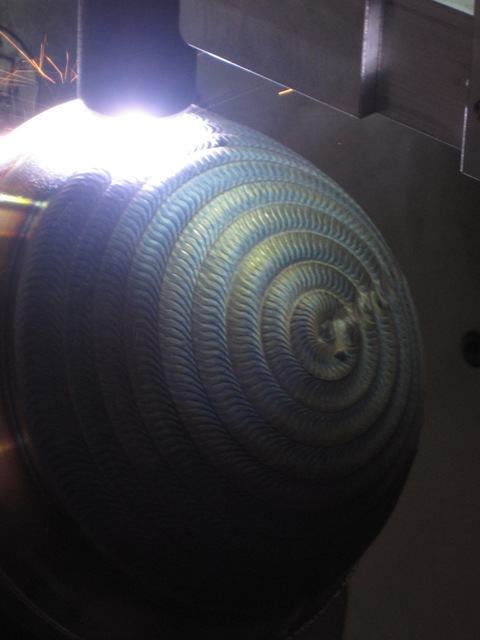

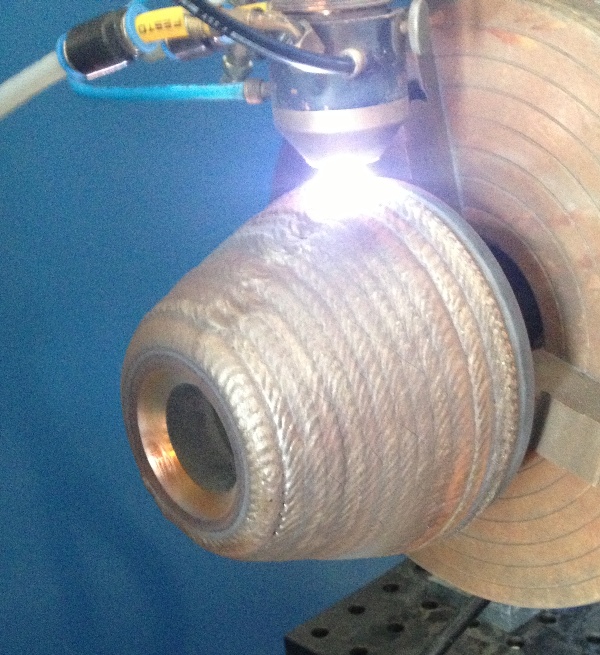

Plasma-transferred-arc-powder-welding (PTA) has a very high energy density. This reduces the heat-input and gives the possibility of a variable, reproducible diffusion zone.

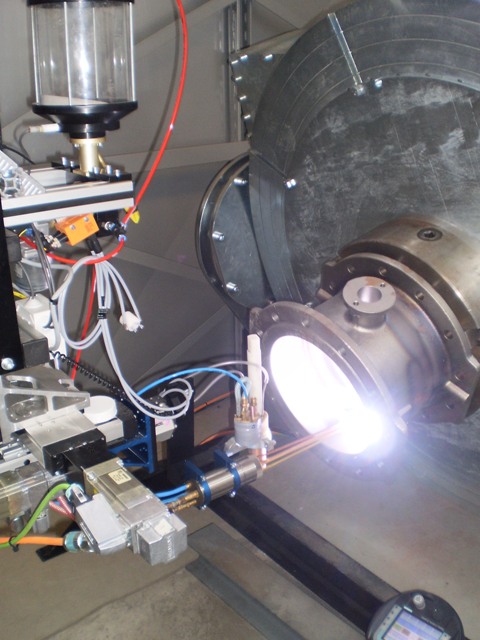

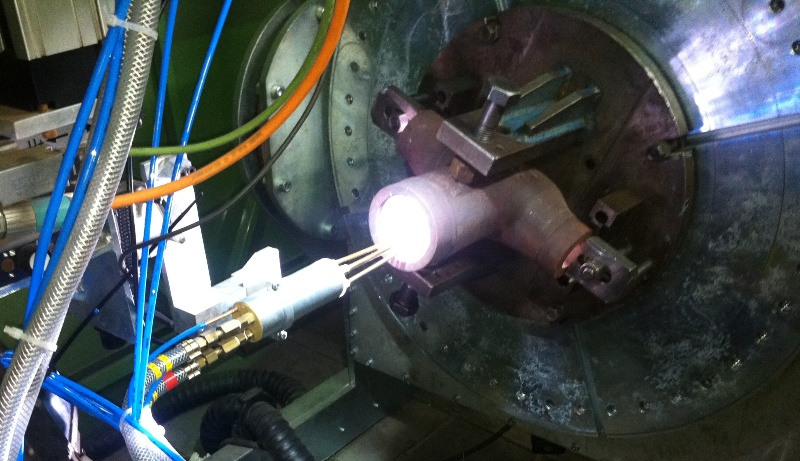

A non-transferred arc (pilot-arc) is ignited between the tungsten electrode and the water-cooled copper-anode using high frequency. This pilot arc usually burns permanently during operation.

For welding an additional arc between the tungsten electrode and the work-piece is used. As plasma-gas and pilot-gas a protective gas (mainly argon) is used.

The PTA powder (additionally a wire may be used) is fed into the transferred arc and is welded on the substrate.

INTERWELD use only inverter power supplies. They have a much higher efficiency and less power consumption than other types of powers supplies.

The main applications for PTA welding are:

- Valve-seats and –cones in combustion engines

- Cladding of tools

- Turbine-blades

- Sliding and sealing surfaces of armatures (gas, water and acid)

- Plungers and moulds in the glass-industry

- Pump parts, etc.