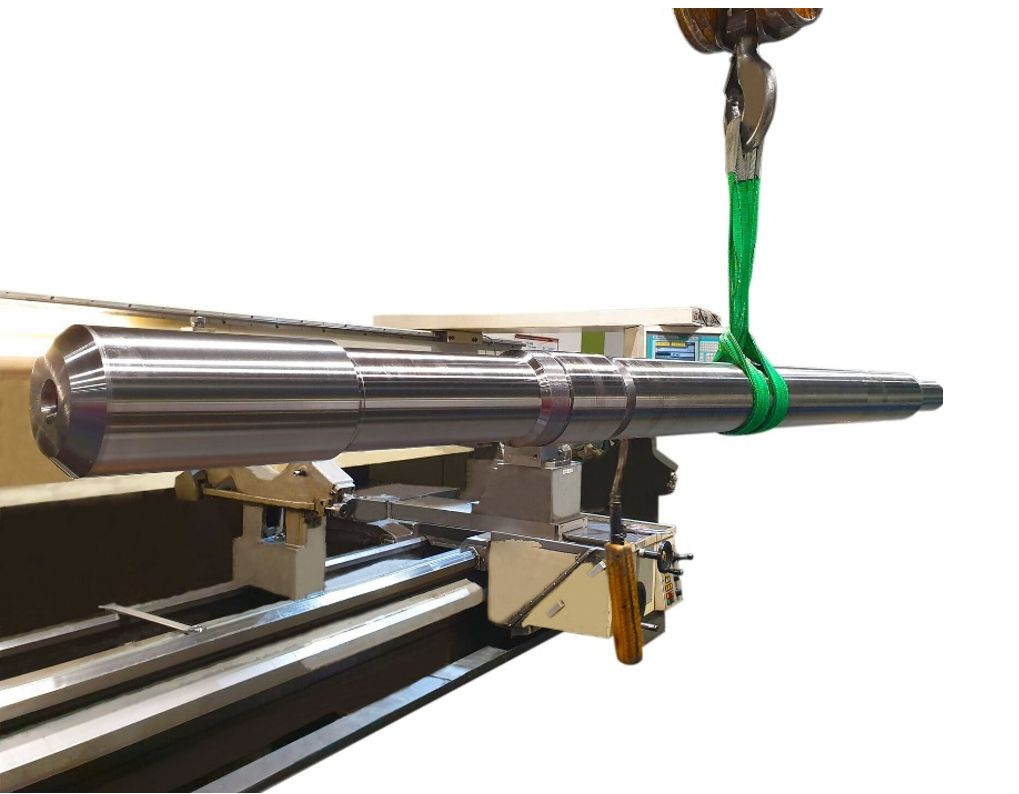

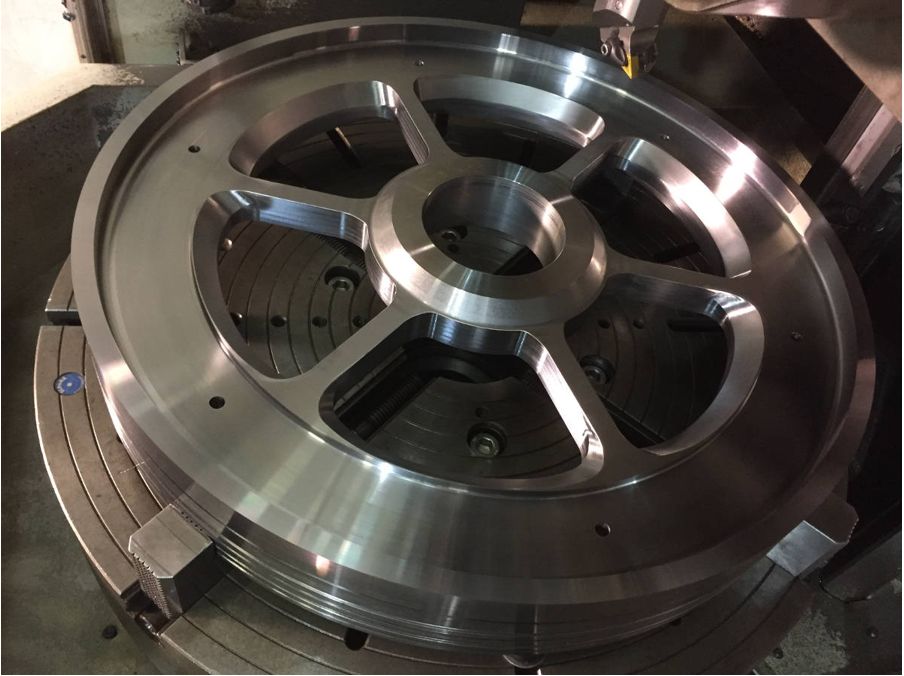

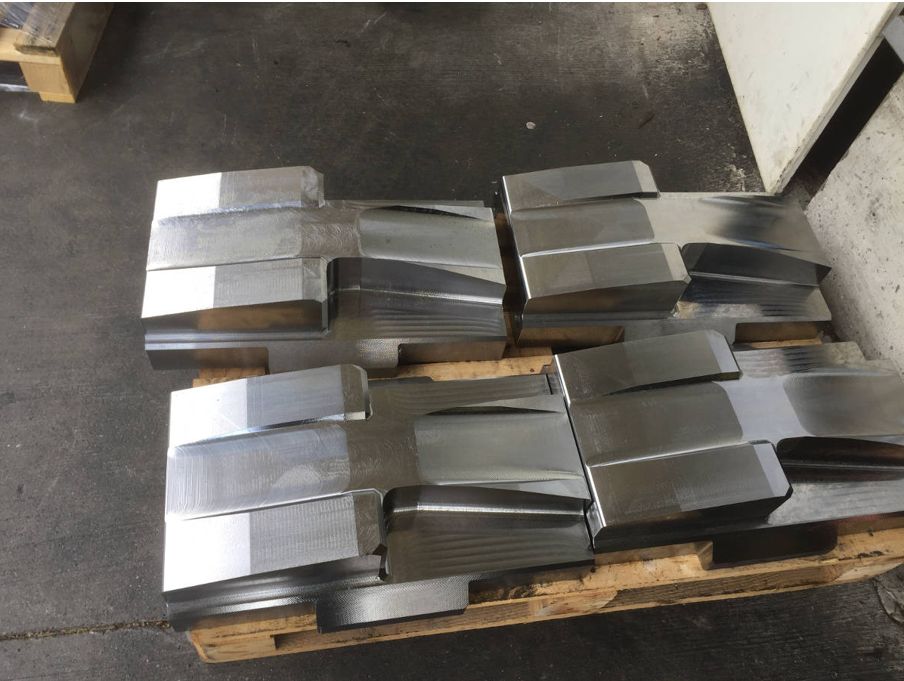

In our workshops and with our long-standing cooperation partners, we manufacture components using CNC and other machines according to customer specifications and drawings.

These parts can also be coated (thermal spraying, build-up welding, etc.).

manufacturing technologies:

- CNC milling and turning; up to 5 axes; maximum X = 5000 mm; Y = 2500 mm; Z = 1600 mm; maximum workpiece weight 12,000 kilograms

- Turning maximum diameter = 2500 mm; length = 1000 mm; max. 3000 kg

- Turning maximum diameter = 1100 mm; length = 4000 mm; max. 5000 kg

- Rotary carousel; maximum diameter = 2000 mm; length = 1800 mm; max. 16000 kg

- Milling machines

- Drilling machines

- Laser cutting

- Welding

- Electrical discharge machining

- 3D laser scanning

- Grinding machines (specializing in the reworking of ceramic and tungsten carbide coatings) Slide 480 mm; L = 2700 mm up to 1000 kg

- Metals, light metals, and plastic parts

We use state-of-the-art machines and software to ensure maximum precision and efficiency.

Our equipment enables us to process everything from simple 2D shapes to complex 3D designs.

Each component is manufactured and tested with the utmost care to meet the highest quality standards.

We would be happy to advise you and prepare a detailed quote.

Send us your details by email to